|

|

|

Wood Heat Controller |

|

|

|

|

|

Tschmidt |

|

2/25/2013 |

Tomattschmidt.com

http://www.tschmidt.com/

|

We have been heating with wood ever since we built our home almost thirty years ago. In addition to space heating wood provides most of our winter hot water. Thirty years ago heating with wood was seen as rather quaint and mainly for rural poor. Now a days heating with wood or wood pellets is considered cost effective green energy. This Paper discusses purpose built controller designed to increase safety and maximize efficiency. Ionization type fire alarm and temperature sensor monitor stove area for unsafe conditions. Air temperature near stove is used to control circulator fans. Flue temperature is displayed and alarm sounded if stove runs too hot. Circulator pump mixes preheater water with electric water heater to increase thermal efficiency. |

Table of Contents

Wood Heat Safety and Temperature Control System..

Controller Theory of Operation

Overview

When we designed our home looked into various ways to heat it. Final design was wood stove located in walkout basement. Electric resistive baseboards serve as backup heat source. Stove is located in center of basement. Multilevel stairway near stove allows unimpeded airflow. Small fan above stove blows hot air up and larger second floor fan blows air back into basement. Due to high level of insulation even without fans there is minimal temperature stratification. This is important during power outages so area around stove does not get too hot.

As former city dwellers it took a while becoming comfortable heating with wood. Used Pine construction scraps first time I fired up stove. Quickly learned, to my chagrin, kiln dried softwood produces an incredibly hot fire. Stove is Tempwood (no longer in business) top loader rated at 55,000 BTUs. Two air inlets control temperature. They run wide open when fire is started then closed down to control temperature. Stove works well but is entirely manual.

At first we used a magnetic thermometer to monitor flue temperature. It was easy to dislodge and did not provide audible over temperature warning. If inlets were not closed down in a timely manner stove ran very hot until someone noticed and went downstairs to damp it down. Obtained several used digital temperature panel meters with BCD outputs and replaced thermometer with a Type J thermocouple in flue. I designed a simple comparator circuit to sound audible alarm if stove gets too hot.

A few years later added hot water preheater. Installed Holly Solar Products stainless steel heat exchanger in stove and a 30 gallon insulated storage tank. System is entirely passive. Stove mounted heat exchanger forms a thermo siphon loop. Heated water, being lighter than cold, rises to top of tank pulling in heavier cold water from bottom. As long as stove is hotter than water heat is transferred from stove to water. A pressure temperature relief valve PTRV is plumbed into tank. It opens if water gets too hot. This is an important safety feature as a boiling water explosion is extremely dangerous. Mythbusters did an experiment to see what happens when a water heater explodes due to excessive pressure, video is pretty dramatic.

Preheat tank is plumbed into electric water heater cold water feed. As hot water is used electric tank draws replacement water from preheat tank. When stove is not in operation electric heater operates normally. When stove is operating “cold” water entering heater is warmer than normal reducing or eliminating need for additional heat. Worked so well when I first hooked it up Power Company asked me to explain why our electricity consumption had gone down.

Passive system works well and has been trouble free for years but does have a drawback. During periods of cold weather and low hot water consumption preheat tank gets hot enough to open PTRV discharging excess water. Having worked hard cutting/stacking/splitting cordwood this waste of energy and hard work was rather heartbreaking. Finally got around to addressing this issue.

Wood Heat Safety and Temperature Control System

Safety and control functions are implemented with a combination of off the shelf and custom built devices. Design has evolved over the years. Most recent upgrade was hot water preheat controller prompting this paper.

Safety

Stove area is protected by interconnected fire alarm. It is an AC powered battery backup ionization detector wired to detectors on other floors. Battery backup is important during periods of power failure to ensure fire warning. In addition there is a temperature detector in ceiling near the stove. If air temperature exceeds 190 degrees F (87.8 C) alarm sounds. This is a safeguard in case stove is operating normally but overheating for extended period.

Type J thermocouple measures flue temperature. Thermocouple is wired to digital temperature display. An alarm sounds if flue temperature exceeds 500 C (932 F) providing a reminder stove is running too hot and needs to be damped down.

Air Circulation

Thermostat monitors air temperature near stove and turns on a pair of fans. Fans reduce temperature stratification. They are not absolutely required allowing safe operation during power outages. A small fan is located directly above stove blowing air into living room. A second larger fan, located on second floor, pushes air back to basement.

Water Preheater

After many years of procrastination finally decided to tackle water preheater overtemp issue. Installed a small recirculate pump and check valve between electric water heater hot-water outlet and pre heat tank cold-water inlet. When water in preheat tank reaches set point temperature the pump circulates water out of the 55-gallon electric water heater back to the cold water feed of the preheat tank thus lowering preheat tank temperature. This increases total hot water storage capacity from 30 to 85 gallons. A side benefit of lowering preheat tank temperature is increased energy capture. Using the electric water heater for additional storage increases total energy storage capacity by about 50%. We rarely have a situation anymore where the PTRV dumps excess hot water. Part of this is also a lifestyle choice. Knowing we have lots of hot water becomes a good time to do extra laundry.

Well water entering preheat tank is roughly 7 degrees C (45 F) in winter. Raising water temperature to 70 C (158 F) takes 28,239 BTUs (158 – 45 x 30 gal x 8.33 BTU).

Electric water heater is 55 gallons set to 49 C (120 F). Increasing water temperature to 70 C takes 17,410 BTUs (158 – 120 x 55 x 8.33 BTU).

It takes about 8kwh to raise 30 gallons to 70C at a cost of $.15kwh each tank of water heated by the stove saves about $1.20. Adding in the electric water heater capacity saves another 5kwh costing $.75. Actual savings of course depends on stove operating time and water usage. Over the lifetime of the system, with a family of four, winter hot water energy consumption is about half compared to summer.

Note: in calculating BTUs we are ignoring effect of temperature change on weight.

Pump set point is set to 140F; this is 20 degrees higher than water heater thermostat.

------------------------------- Caution ------------------------------------------

Water temperature above 120 F dramatically increases risk of being scalded.

Use of tempering valve or antiscald valve decreases risk.

|

Temperature |

Time to produce 3rd degree burns on adult skin |

|

160 F (71 C) |

˝ second |

|

150 F (66 C) |

1.5 seconds |

|

140 F (60 C) |

5 seconds |

|

130 F (54 C) |

30 seconds |

|

120 F (49 C) |

5 minutes |

|

110 F (43 C) |

3 hours |

|

100 F (38 C) |

Safe Temperature |

Controller Theory of Operation

Figure 1 Wood Heat Controller - front panel

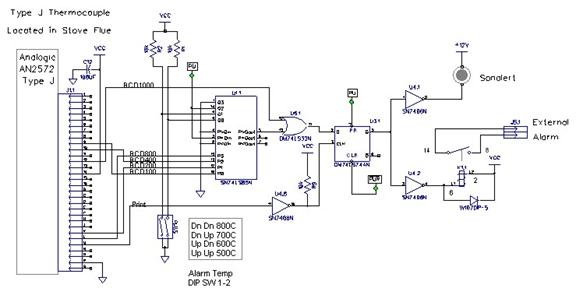

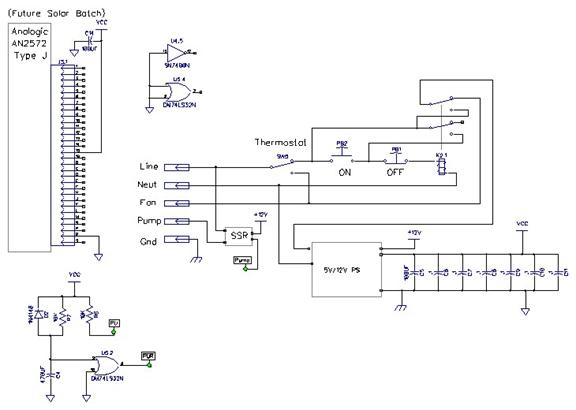

Controller consists of three Analogic AN2572 Type J thermocouple digital displays with BCD outputs. Top display monitors wood stove flue temp. Middle displays preheater water temperature. A third is intended for future batch solar water heater.

User controls consist of a line voltage thermostat and on and off push buttons. When stove is started on button is pressed latching power relay energizing unit. Pressing off button deenergizes relay powering unit down.

Fan Control

Line voltage thermostat monitors air temperature near stove. When temperature exceeds set point it turns on fans. Fans are on as long as temperature is above set point.

Thermostat has a second function. It deenergizes power relay but continues to power up unit. Even if unit was not started manually once fans turn on flue temp and preheat function becomes active. When ambient temperature falls below preset value controller and fans are shut off.

Flue Temperature Monitor

A Type J thermocouple probe is inserted into flue pipe a couple of feet above stove. Digital readout displays flue temperature. A digital comparator monitors BCD temperature output. Display PRINT command latches current temperature reading. If temperature rises above set point activates Sonalert audible alarm. I included a reed relay contact closure output to activate another alarm but so far that feature has not been needed. Sonalert is loud enough to be heard throughput house. Alarm trip point can be set between 500-800 C in 100-degree increments by two DIP switches.

Preheater Pump

This is the most recent upgrade. Normally a differential temperature controller would be used in this type of application. I opted to simply monitor preheat tank temperature. I did this for two reasons:

1) Did not have a differential temperature controller

2) At very high temperature even if preheat and electric heat tanks are at same temperature keeping water flowing minimizes temperature at thermo siphon cold water inlet reducing chance PTRV will open.

Thermocouple is attached to pre heat tank hot water outlet. Digital readout displays preheat tank temperature. BCD comparator is similar to one used for Flue temperature with addition of a 555 timer configured as a one shot. When set point is reached SSR is activated turning on pump and LED indicator. Pump activation triggers 555 timer. 555 output is looped back forcing pump to remain running for several minutes regardless of temperature reading. This creates hysteresis eliminating short cycling pump. Pump activation temperature can be set between 50-80 C in 10-degree increments by two DIP switches.

Controller Schematic

Figure 2 Flue Temperature Monitor

Figure 3 Preheat Recirculate Pump Control

Figure 4 AC Switching

Conclusion

System has been in use many years; keeping us warm in an environmentally friendly fashion, providing hot water and saving money.

Heating with wood requires some accommodation – it involves more than just setting temperature on a thermostat. Having a stack of wood outside is very reassuring in these troubled times. No matter what happens we know at least we will be able to stay warm. In December 2008 Northeast was hit by a severe ice storm knocking out power to thousands of people in Southern NH. We lost power for six days but did not have to worry about freezing pipes or going to a shelter because we were able to stay warm without electricity.

Often time’s environmentally conscious projects are overly complex and expensive. This paper describes what we have been able to do using a combination of new and used components and a little ingenuity. Hopefully it will encourage others to experiment.